The sheets are the most necessary bedding parts which can complement any bed. Depending on the weaving technology used, the bedding material can determine the comfort level you get during sleep time.

Percale and satin are known types of fabrics that are commonly used in sheets and bedding.

The difference between these two types of bedding is in the processing (the weaving) and not the material. They can be made from the same material, but the processing helps to make each truly precious and adapted to different sleepers and weather conditions. The particular processing makes percale sheet a comfortable, velvety fabric and satin fabric, smooth and beautiful.

In this percale vs sateen sheets comparison article, we’ll see the difference between the two types of sheets and advise you on which one to choose.

It would be wrong to promise that we will tell you which one would be better. It all depends on individual preferences. However, both types of fabrics are some of the most used for bedding. But in the end, you will have to choose just one. So, which one is better for you: sateen sheets or a percale cotton sheet?

Cotton is a natural textile fiber that is best suited for use in different weaving applications. The work processes that lead to the final result involve different steps. It includes the collection of the cotton ball to the final product, which is the fabric used in the textile industry.

First of all, is the carding process. Here, the wad is opened and untwisted, and the fibers are arranged in parallel while eliminating all impurities.

The next phase is preparation for combing. Here, the carded cotton is gathered and assembled to form a small size and very lightweight canvas, which will be introduced into the combing machine.

During the combing phase, a sort of further carded ribbon is obtained, in which the fibers are homogeneous in length and parallel correspondence.

This will be followed by ironing, necessary to regularize, and the entire combed cotton ribbon uniform. Next is the twisting stage, in which the wrapped fibers will feed the actual spinning process.

Before weaving and depending on the final result to be obtained, different washing and dyeing procedures can alternate according to the characteristics of the use of the fabric itself.

The waste from the cotton processing will make up less valuable yarns or will be used in the production of wadding for various uses. The most famous of these wastes is the cotton wool that we use at home.

So, having explained the general weaving process of cotton percale or sateen sheets, which is better? How are they woven?

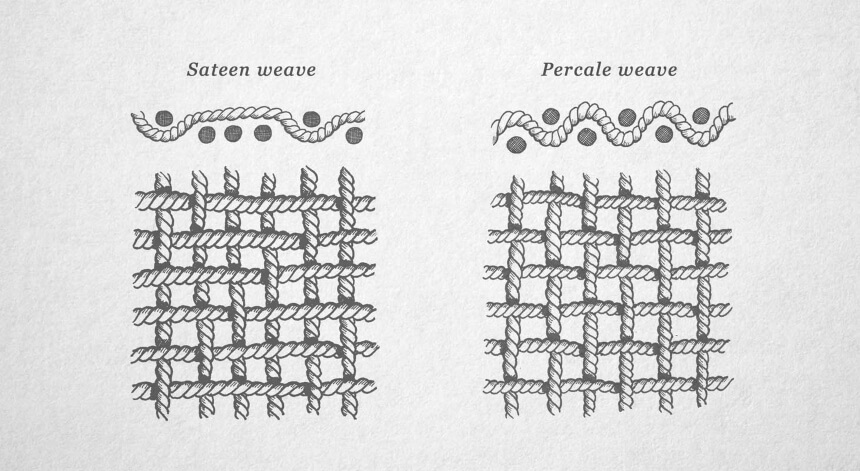

Percale sheets are woven to be light and breathable, so they are recommended for hot sleepers and hot weather. The lattice weave gives them a less smooth glide than satin. They feel fresh and crisp on the skin – much more like a starched than a draped material. The tight weave sheets have less space to insert additional threads. So they generally have fewer threads and weigh less than satin, too.

The looser and extended weave of sateen fabrics allow more light to bounce on them, which adds shine to the cotton fabric. Plus, it makes them vulnerable to snags. So, manufacturers pack more threads per square inch. This produces sheets that are stronger and simpler than percale but also warmer and thicker.

Percale sheets have the mixture of the factors that every superior fabric should have – softness combined with resistance. But what is percale, and why is it so coveted for some textile creations?

Percale materials are plain and closely-woven Trusted Source Percale - Wikipedia Percale is a closely woven plain-weave fabric often used for bed covers. Percale has a thread count of about 200 or higher and is noticeably tighter than the standard type of weave used for bedsheets. en.wikipedia.org . The sheets are made from fabrics of particular quality and value, and they are obtained by processing natural yarns with plain weave. The process of making them involves weaving the threads in a way that is perfectly perpendicular between weft and warp.

The peculiarity of percale is that it is manufactured with fine yarns with a tight structure, very dense processing, both with carded and combed fabric. Basically, the greater the thinness of the yarn used in the weaving, the more the fabric will be soft and light.

Percale sheets are made from a relatively tightly woven fabric that uses one thread over the other under the type of weave. This gives the fabric construction a simple matte finish. It makes them cool to the touch and very similar to your preferred brittle cotton shirt.

Both the tightness of the yarn and the thread count of the fabric are factors that determine whether the sheet is classified as “percale” or “muslin.”

The value of percale is determined by the number of threads per square centimeter of the fabric, with a count ranging from 40 to 400. This determines the quality of the final result to be obtained and the cost. The best percale sheets are those which have higher thread counts (up to 400). This guarantees durability and a high comfort level during sleep.

The advantages of percale sheets are their extreme softness. The fabric is velvety to the touch, very light, and is resistant to the action of washing and use. These make it the ideal fabric for sheets. Thus, it is one of the best fabrics used in bed linens, especially those that are used in the summer season.

Suffice to say that almost 70% of garments, for apparent reasons of mass textile production, especially for large commercial purposes, are made by consciously omitting the use of the right percentages of natural and artificial fibers. The result is that such textile articles, albeit highly attractive due to the technical evolutions of spinning, often cause skin allergies.

Percale fabrics usually have a good percentage of natural fiber and a minimum of synthetic, perhaps more for reasons of elasticity. In addition to them lasting over time, they are non-allergenic and ideal for sensitive skins.

Percale cotton sheets also have the advantage of retaining the qualities of color brilliance, softness and integrity, despite repeated washing.

Percale sheets are smooth and soft on both sides. Also, when they have a blend of polyester, they are more resistant to wrinkles and pilling.

There is a multitude of percale sheet sets on the market. However, if you want to purchase a percale sheet, our experts recommend the Peru Pima set that features a 415-thread count and provides a luxurious feel.

Percale sheets are particularly valuable and luxurious when made of cotton. They are composed of fine yarns with a tight structure that is dense. It is obtained by working the material with a plain weave that stands between the weft and warp. The finer the thread used for weaving, the higher the quality and lightness of the fabric. Soft and velvety, percale is widely used in particular for the production of bed linen. For products in percale cotton, the quantity of threads per cm2 is often indicated on the packages. The finer these are, the greater the number of threads and therefore the quality.

The satin sheets are smooth and drape all over the body. They provide a comfortable feel when you crawl under the covers.

Their softness comes from the fact that they are made from a piece of very fine fabric and high-quality threads. Often, some factories make them from synthetic fibers like nylon, polyester, and (ugh) acetate. Yes, these materials are perfect for providing that impressive shine but have nothing to do with satin.

Don’t buy sheets that are called “knitted.” If you see any satin sheets at a significant discount, that means they are made with acetate. This is not a good thing because the surface is going to be rougher than what you are looking for. Look for “woven” fabric. Specifically, look for sheets made of woven 100% satin.

Satin sheets are softer and more pleasant to the touch than percale sheets. They have a beautiful sheen that gives the bed a luxurious look and feel. Again, the difference in feel between the satin sheet and also its percale brother is due to the way they are woven. Satin sheets are woven in a single four-thread thread. The number of threads exposed on the surface of the fabric is what gives satin its characteristic shine and silky feel.

Compared to a percale sheet, satin sheets are more prone to snagging. That is why they are generally woven to higher threads so that they stay as close together as possible. However, you can fix problems of snagging in satin sheets by turning your iron on steam and press the area you have the snag to straighten it out.

Finally, you have to note that it is slower to knit a satin sheet than a percale sheet. Perhaps that is one of the reasons satin sheets are generally more expensive than percale sheets.

Sateen sheets are shiny, smooth, extremely pleasant to the touch, and help you sleep cool (although not as cool as percale sheets). Sateen is used for the production of luxury linen and even evening dresses and shirts. Again, the difference with the other types of cotton concerns not the fiber itself but the fabric’s texture. Good sateen sheets, like the California Design Den set, are made of 100% cotton and stand out for their excellent resistance to wear. In fact, it is possible to wash them safely in the washing machine.

However, if you’re sticking with percale or sateen, it is essential to wash them well and dry at a low temperature. If the sheets are not going to be ironed, it is crucial to quickly remove them from the dryer, straighten them and fold them immediately.

During the wash cycle, the cotton fibers lose some of their softness. Ironing them will soften the fibers again and make them more beautiful. In the case of satin sheets, this will help maintain their shine.

The choice of using percale or satin sheets is only a matter of taste. The satin sheets have a smooth and shiny appearance, while the percale needs to achieve this finishing with further processing.

Both percale and satin sheets are cool to the skin in hot weather, but percale sheets perform better in this aspect.

As mentioned in this percale vs. satin sheets comparison article, all 100% cotton sheets, whether percale or satin, are wrinkled, although satin sheets are less prone to wrinkles than percale.

Some consumers prefer the fresh feel of percale sheets, while others prefer the silky feel of satin sheets. Again, it is a matter of personal preference.

The higher the number of threads, the higher the price of satin sheets, and it is more used by luxury and high-demand hotels. There is nothing quite like the sheen of satin to make the bed look luxurious.